We provide industrial boiler and installation services for a range of industries.

Breweries

Steam boilers contribute more to the craft brewing process than just heating ingredients. There’s also the matter of cleaning and sterilising the tools and equipment that are used in brewing, including the mash tuns, Brite tanks fermenters, etc. Breweries have a few different options for going about this, including the use of dry heat or chemicals.

However, steam is the best way to kill spores and bacteria that could linger on important brewing equipment. Breweries can also use the steam from their boilers to ensure their equipment is properly sanitised.

Hospitals

Most hospitals will use steam boilers

This is because they’re highly efficient and can heat a building relatively quickly without relying on gravity.Steam rises and carries itself through a series of pipes within the system, heating the whole building. They’re highly efficient, which is extremely important for large buildings such as a hospital.The use of steam is a very clean and hygienic way of providing hot water. The water is filtered and is evaporated and turned into condensate once it’s gone through the whole system. For example, the steam produced by the boiler can be used to sterilise medical equipment.

The Food Industry

Boilers are an essential part of food processing and are used to heat, sterilise, and pasteurise food and beverages. They are also used to create steam, which is essential for cooking, drying, and other processes.

The food industry is emerging as one of the dominant industries in the world, and therefore the boilers for the food industry must be of the highest quality and efficiency for smooth processing operations.

Boilers for the Food Industry are generally used to process food, meat, vegetables, beverages, bakery and confectionery, and food packaging.

Using our expertise to provide innovative solutions to meet our customers’ needs

Operational Needs and Load Demand

Every business has different needs when it comes to hot water and steam. Do you plan to use the steam system strictly as part of your manufacturing process, or will it serve multiple uses? Do you also plan to incorporate your boiler into your heating system and/or hot water heater? Is steam pressure a consideration? The answers to these questions will help you make a determination as to your overall required steam output and BTU needs — and by extension, your boiler sizing.

Why Choose Steam Pickett?

Cost Optimisation

There are many things to consider when purchasing and installing a new boiler or replacement boiler for your business. We will guide and work with you for the growing needs of your operation.

Proven Solutions

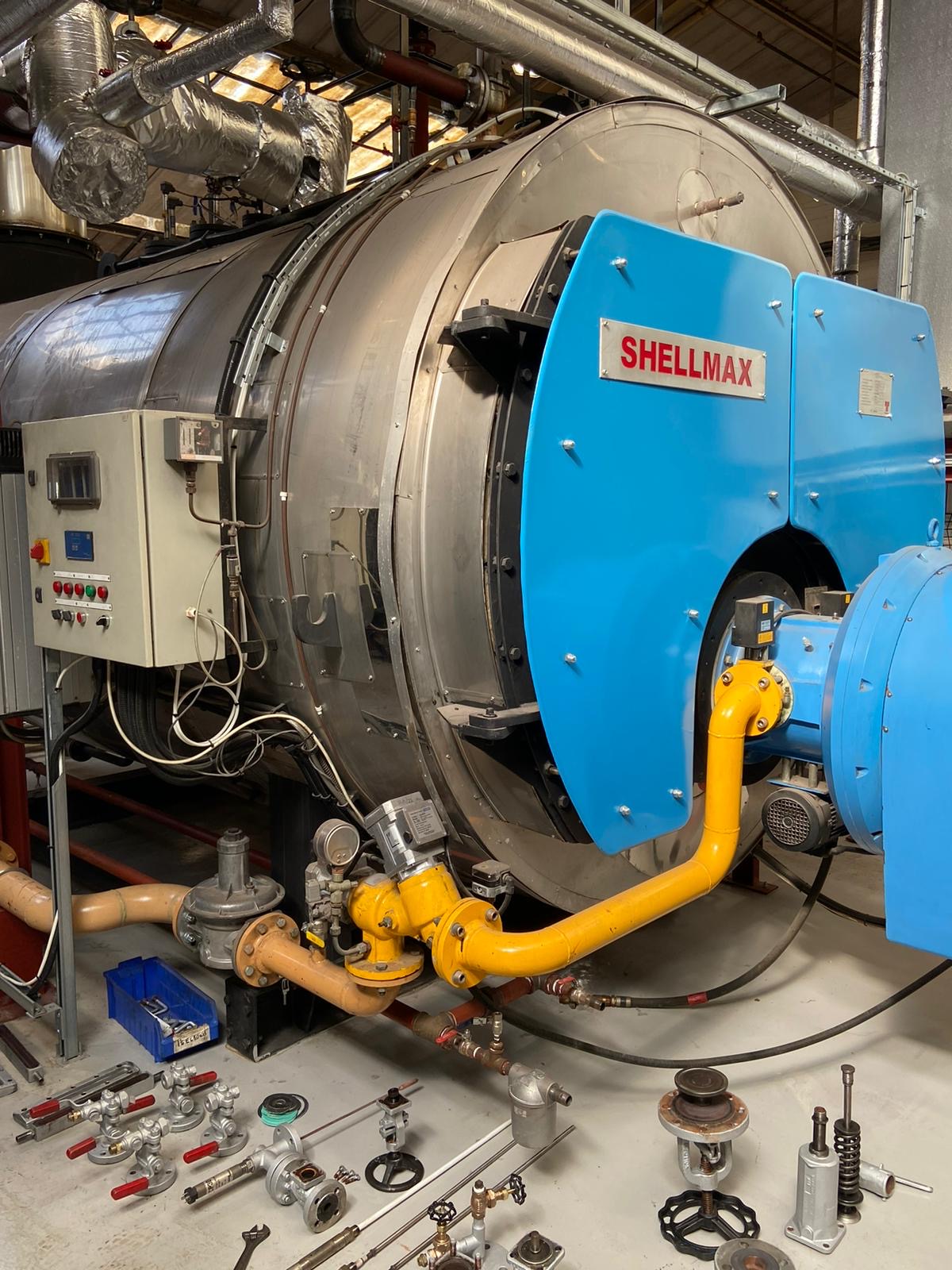

Our experienced and qualified mechanical team combine planning, technical expertise, and adaptability to ensure seamless installations. Our fully managed services provide our clients with proven, assured turn-key solutions.

Experience

Our wealth of experience means we can install boilers and ancillary equipment to suit clients’ requirements, whether a small skid-mounted boiler plant or a large multi-boiler installation.

Steam Boiler Plant Efficiency

We undertake a range of surveys and remedial work to improve efficiencies and reduce fuel bills. Thermal Efficiency Testing, Fuel-to-Steam Efficiency and Steam Trap Surveys.

Conserving Energy

Inefficient or faulty steam plant can cost process and manufacturing companies many thousands of pounds in wasted energy costs per year.

Every business has different needs when it comes to hot water and steam. Steam Pickett can help your business save money and energy because you’re never producing more steam than you need.

Efficiency & Enviroment

While we are proud of our traditions and experience, we also move with the times, continually reevaluating processes and applications, to ensure compliance, ease-of-installation and compliance.

Improving boiler efficiency, improved energy efficiency of plant processes, reduced consumption of water and emissions, all of which have a significant and positive impact on the environment.

Our Carbon Footprint

In accordance with national and international commitments on climate change, we endeavour to continuously reduce the carbon intensity of our business, implement initiatives to cut our carbon emissions and improve the sustainability of our operations, and help our customers to do the same.